Temperature and Humidity Test Chamber

Temperature & Humidity Test Chamber

Temperature & Humidity Test Chamber is widely used in the temperature variation tests, cold resistance tests and storage with low-temperature in the fields of aerospace, aviation, electronics, instrument, electric products, materials, parts and components and equipment to analyze and evaluate the property and performance of the samples under the simulated conditions

Temperature & Humidity Test Chamber

Temperature & Humidity Test Chamber is widely used in the temperature variation tests, cold resistance tests and storage with low-temperature in the fields of aerospace, aviation, electronics, instrument, electric products, materials, parts and components and equipment to analyze and evaluate the property and performance of the samples under the simulated conditions

| Model | TH-1000 | TH-225 | TH-500 | TH-800 | TH-1000 |

| Internal dimension (mm) | 450*450*500 | 500*600*750 | 800*700*900 | 800*1000*1000 | 1000*1000*1000 |

| Overall dimension (mm) | 1050*880*1440 | 1050*1020*2000 | 1320*1320*2170 | 1470*1520*2315 | 1670*1520*2315 |

| Technical structure: | |||||

| Temperature range | -20oC to +150oC | -20oC to +150oC | -20oC to +150oC | -20oC to +150oC | -20oC to +150oC |

| Low type | I: -40oC II: -60oC III:-70oC | I: -40oC II: -60oC III: -70oC | I: -40oC II:-60oC III: -70oC | I: -40oC II:-60oC III: -70oC | I: -40oC II: -60oC III: -70oC |

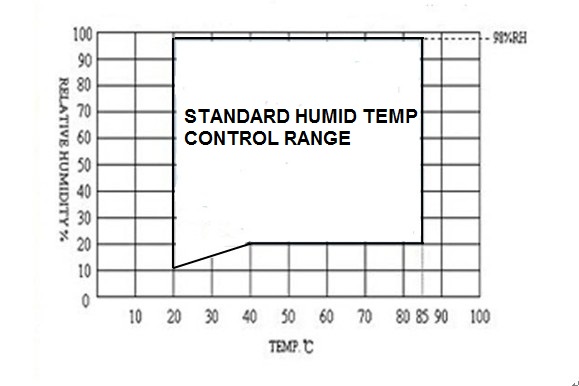

| Humidity range | 20% to 98% RH | 20% to 98% RH | 20% to 98% RH | 20% to 98% RH | 20% to 98% RH |

| Temperature fluctuations | ± 0.5oC | ± 0.5 oC | ± 0.5oC | ± 0.5oC | ± 0.5oC |

| Temperature deviation | ± 2.0oC | ± 2.0oC | ± 2.0oC | ± 2.0oC | ± 2.0oC |

| Humidity deviation | ± 2.5% RH | ± 2.5% RH | ± 2.5% RH | ± 2.5% RH | ± 2.5% RH |

| Heating rate | 3oC/ min | 3oC/ min | 3oC/ min | 3 oC/ min | 3oC / min |

| Cooling rate | 1oC/ min | 1oC/ min | 1oC/ min | 1oC/ min | 1oC/ min |

| Control system: | |||||

| Controller | |||||

|

|

Temperature Humidity Test Chamber Model TH-1000

|

Model

|

TH-1000

|

|

Internal dimension (mm)

|

1000*1000*1000mm

|

|

Overall dimension (mm)

|

1600*1480*1980mm

|

|

Technical structure

|

|

|

Temperature range

|

-20℃ ~+150 ℃

|

|

Humidity range

|

10% ~ 98% RH

|

|

Temperature fluctuations

|

± 0.5 ℃

|

|

Temperature deviation

|

± 0.5 ℃

|

|

Humidity deviation

|

±3.0% RH

|

|

Heating rate

|

3 ℃ / min

|

|

Cooling rate

|

1 ℃ / min

|

|

Air Ventilation

|

Air exchange for clear workroom 12m3/ h

|

|

Air flow rate 0.5m3/h

|

|

|

Noise

|

Under 70dB

|

|

Control system

|

|

|

Controller

|

|

|

PC Link with software, R-232 interface

|

|

|

Temperature Sensor

|

PTR Platinum Resistance PT100Ω/MV A-class

|

|

Temperature Resolution

|

± 0.001 ℃

|

|

Humidity sensor

|

Dry and wet bulb sensor

|

|

Humidity Resolution

|

± 1%RH

|

|

Heating system

|

Independent Nichrome electronic heating system

|

|

Cooling system

|

French TECUMSEH compressor

|

|

Humidification system

|

External isolation, stainless steel surface evaporation humidifier

|

|

Dehumidification system

|

Evaporator

|

|

Water supply system

|

Automatic water supply, Water purification system, Water saving

|

|

Circulatory system

|

Cold resistance and low noise centrifugal wind wheel

|

|

Material

|

|

|

Exterior material

|

|

|

Interior material

|

|

|

Insulation window

|

Double thermostability silicone rubber sealing

|

|

Timing Function

|

0.1~999.9 (S、M、H) settable

|

|

Power Supply

|

AC380V 50HZ Three-phase five little system

|

|

Ambient Temperature

|

5℃~+30 ℃ ≤85% RH

|

TH-1000 chamber explanation

l TH-1000 capacity is 1000L(Workroom dimension is 1000mm*1000mm*1000mm).

l TH-1000 chamber temperature range(-20 degree to +150 degree) and humidity range (10%~98%).

l Before doing the test, the workroom can be clean by 12m3/h air ventilation. We install activated carbon in the air inlet, so air will be clean before entering the workroom.

l After reaching the set points of temperature and humidity, then put the wood products into the chamber.

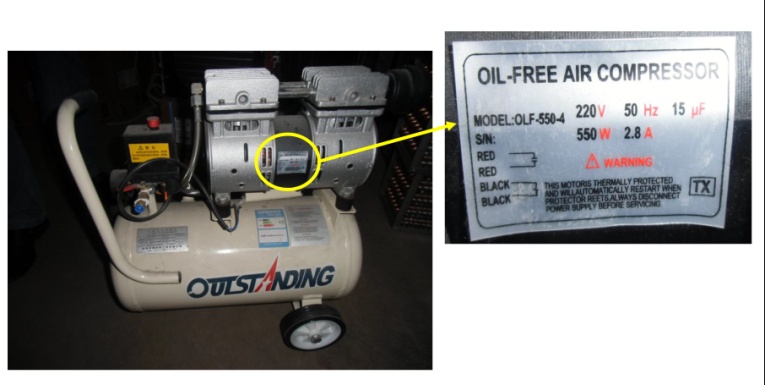

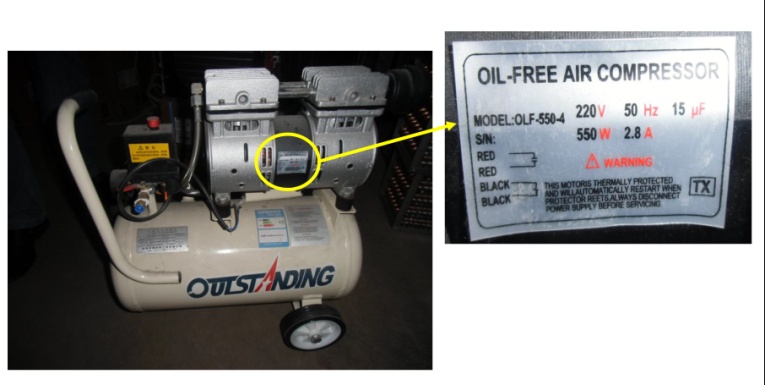

l We will provide a air pump for supplying the compressed air. The compressed air also be clean before entering the workroom by activated carbon. The compressed air flow velocity will show on the flowmeter, and you can calculate air volume according to testing time and air velocity.

l You can set air flow rate on the flow meter by valve. Flow meter can display and set air flow velocity.

l The Controller can control and display temperature and humidity. and only show workroom pressure.

l We can install 2 pcs valves to outlet air. The washing bottles will be connected to these valves for absorption formaldehyde gas.

l We will supply the washing bottles.

Temp-Humid. Chart

How to operate this chamber.

First, this chamber don't need any installation, you can directly use it. Before doing the test, you can set 12m3/ h air exchange for clean the workroom.

Second, you need set points of temperature and humidity, and adjust air exchange to 0.5m3/h.

Third, After finished test of all set points, you can open valve, Washing bottles will absorb formaldehyde gas.

Design and Construction

Test area

Test area is made of stainless-steel, the real wall of test area with

chip-type wind board and return air inlet to achieve air flow.

Left wall opened test hole (Φ 50mm, Φ125mm).

Test hole is stainless steel with silicone plug.

Temperature sensor and Dry and wet bulb sensor installed on right wall.

Pressure sensor

Chamber with 2 stainless steel shelves which can be adjustable.

Temperature and humidity air flow

Air flowing out from top of wind board which control air direction, and return into air let to achieve air flow .

Air inlet and Air outlet

Air inlet located on the left of the chamber;

Air outlet located on the top of the chamber, and a covert tube will extend to the bottom of the controller.

Control panel

Controller is located on right side of test chamber.

5.7" programmable color display touch screen controller from South Korea.

Controller can show temperature, humidity, workroom pressure.

Programmable controller can adjust and set temperature and humidity.

Controller can’t control workroom pressure.

Programs reach to 999 groups and 999 sections

R-232 / R-485 interface, PC Link with software , LAN network interface

Touch screen control panel with color LCD display

Air compressor

Supply compressed air

Flowmeter

Flowmeter is installed on the around air inlet.

Flow meter is adjustable and settable, so you can set any point at any time by manual Valve.

Air flow velocity can be display and set on the flowmeter.

Cooling system

Cooling unit is French TECUMSEH compressor.

Environment friendly Refrigerant R404A & R23

Single compressor for the -20℃ level

Humidification system

External isolation, stainless steel surface evaporation humidifier

Automatic water supply, Water purification system, Water saving

Sensors

Temperature sensor PT-100 A class

Resolution: temperature: ± 0.01 ℃

Humidity sensor Dry and wet bulb sensors

Resolution: ± 1%RH

Pressure sensor

Washing bottle

Washing bottle absorb formaldehyde

Large viewing window

Heated viewing window with interior lighting, preventing frosting.

Viewing window size is 30*35cm ,.

You can observe the change of specimen inside internal workroom

Safety protection

Humidifier dry-combustion protection

Independent over-temperature protection,

Water shortage protection

Over-current protection

Refrigerant high-pressure protection switch

Earth leakage protection and so on

Power supply and Wiring

380V, 50 Hz 10% +/- three-phase-five-wire system

Package with Export Standard Wooden Box

Can be used for Sea, Air,Railway, Truck transportation.

|

|

|

Environment conditions

Temperature:5 ℃ --35 ℃ , Relative humidity: ≤85%, pressure: 86kPa—106 Kpa

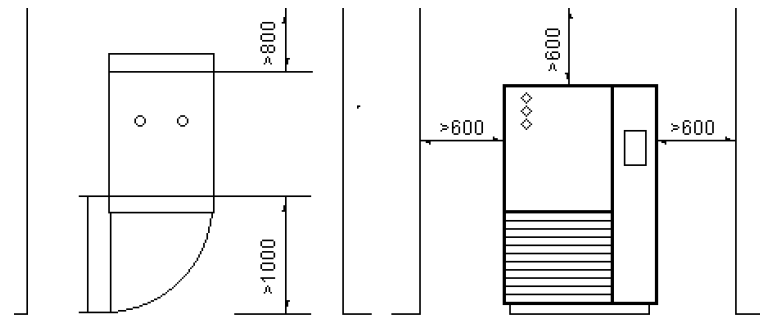

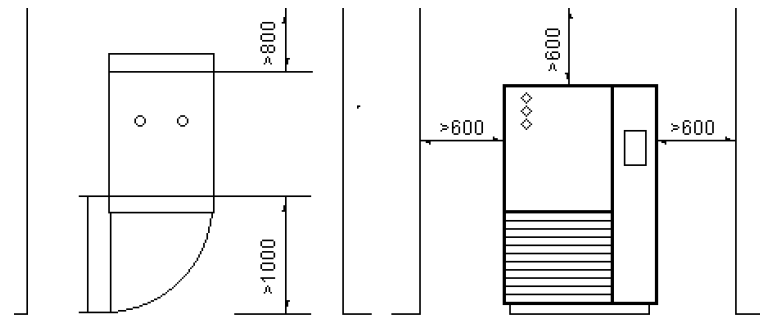

Space conditions

Chamber shall be installed on flat floor, with good ventilation

Nocombustible material, explosive material or strong vibrationaround.

No direct sunlight or other heat sources direct radiation.

No strongelectric fieldaround.

About Us

Xi’an LIB environmental simulation industry is a manufacture and exporter of climatic test chambers in China, and have over 8 years overseas market in test chambers to more than 25 countries. LIB adhered to “Quality”, “Service”, and “Trust”. LIB main products are:

* Temperature and humidity test chamber

* Temperature and humidity test chamber * Salt Spray test chamber

* Dust / water Ingress test chamber

* UV weather test chamber

* Xenon arc test chamber

* Thermal shock Test chamber

* Large Walk-in room

And more…

Test equipments are widely used in military industry, engineering controls project, testing institutes, universities, laboratory ,aerospace, electronics, instrumentation, home appliances, auto parts, research and quality inspection Area.

|

|

|

|